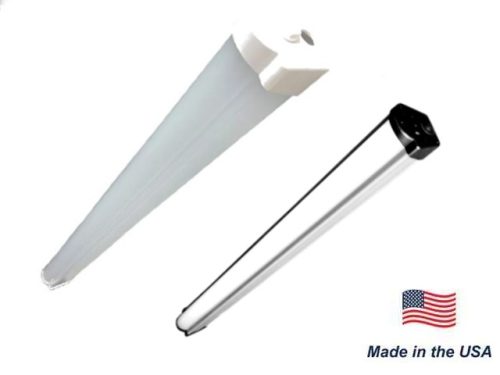

LED Cold Storage Lighting for Industrial Cold and Freezer Applications

LED Cold Storage Lighting for dependable performance in extreme environments. Increase productivity with significant energy savings and lower maintenance costs. All fixtures are made in the USA and are BAA Compliant. Ideal for Cold and freezer storage for in distribution facilities, manufacturing, production, pharmaceutical and food processing. One of the most significant benefits of LED cold storage lighting lies in its energy efficiency. It’s remarkable to note that LED lights consume approximately 60-70% less energy than incandescent bulbs and can be about 50% more efficient than fluorescent.

Energy Savings

1st Source LED Cold Storage Lighting delivers 60% to 70% energy savings over outdated HID and fluorescent systems. LED also emits less heat into the environment for reduced load on refrigeration systems. Immediate re-strike requires no warm up period versus outdated HID fixtures which begin to draw power before emitting light. Add dimming and occupancy sensors for extended savings.

Performance

1st Source LED Cold Storage Lighting is engineered for peak performance in temperatures down to -30 degrees F. Cold ambient or blown air can wreak havoc on unrated or unprotected components causing reduced lumen output, flickering, and ultimately premature outages. Considerations for fluorescent and HID lighting are now outdated due to poor performance, short life span and high energy consumption. LED technology is now widely recognized as the best option for cold storage applications.

Maintenance

1st Source LED Cold Storage Lighting will dramatically reduce maintenance costs associated with bulb and ballast replacement. A 100,000 hour rated life ensures lower maintenance and fewer component swap outs. Converting to Linear LED lighting eliminates constant fixture maintenance in higher locations or hard to reach areas.

Durability

Sub-zero temperatures can cause severe issues with poorly designed light fixtures. Especially if they are not engineered for cold or freezer applications. With over 20 years of design and manufacturing experience, 1st Source Cold Storage Lighting is be built for dependable start up and optimal performance over the life of the fixture. Every fixture is bench tested prior to shipping and backed by a 5 year product warranty.

Dimming and Controls

All of our LED Cold Storage Lighting fixtures are low voltage and/or line voltage capable. Fixtures may be prepared with dimming leads to run low voltage wiring to a dimmer switch or may be specified with line voltage dimming. Integral control sensors may be added to the fixture to control on/off for occupancy or configure desired dimming levels. Fixtures may also be controlled for on/off with a room ceiling or wall sensor located preferably near the entrance. 1st source also offers wireless systems for control via remote, PC or mobile device.

Longevity

Another compelling advantage is the durability and longevity of LED lights. Typically, they last significantly longer—often exceeding 100,000 hours—which starkly contrasts with the mere 10,000 hours offered by fluorescent bulbs. Transitioning to LEDs helps businesses save time and resources spent on routine maintenance. A facility manager shared their experience: “After switching to LEDs, we appreciated a dramatic reduction in bulb replacements, slashing our maintenance costs by an impressive 30%.” These testimonials reflect how investing in quality lighting solutions can free up valuable labor hours and financial resources. As you become acquainted with these incredible benefits, you’ll notice there’s yet another crucial aspect that can’t be overlooked: improved visibility.

Enhanced Visibility

Good lighting enhances workplace safety and productivity, especially within cold storage areas where clarity is paramount. LED lights possess a higher Color Rendering Index (CRI), which leads to better color perception and visibility. In fact, studies show that proper illumination from LEDs can boost visibility by as much as 20% compared to traditional lighting options. This increased brightness reduces accidents, empowers workers to identify potential hazards more quickly, and creates an overall safer environment for handling food products or delicate materials.

Furthermore, the unique design of LED fixtures allows them to emit less heat compared to older technology. This feature is particularly beneficial in cold storage settings where maintaining lower temperatures is vital. By emitting minimal heat, LED lighting assists in keeping refrigeration units working optimally while reducing overall cooling demands.

Enhancing Warehouse Efficiency with LED Lighting

Efficiency in warehouse operations is directly tied to the effectiveness of the lighting. This connection becomes especially clear when considering features such as improved visibility, reduced heat emission, and the integration of smart control systems. Imagine a warehouse illuminated with traditional fluorescent fixtures consuming around 1000 watts; by making the switch to LED lighting, that requirement could drop to around 500 watts. This drastic reduction not only translates into lower electricity bills but also means reduced strain on your electrical systems, allowing for a more sustainable operation.

Reduced Heat Emission

Unlike traditional lighting options that generate considerable heat during operation, LEDs are designed to run cool. This characteristic is particularly beneficial in cold storage facilities where maintaining specific temperature ranges is essential. By using LED lighting, warehouses can minimize the load on their cooling systems, leading to improved temperature regulation and reduced energy costs. The ability to keep temperatures stable without excessive strain on refrigeration units translates into cost savings and preservation of sensitive goods that could be adversely affected by heat fluctuations. As we look even further into modernization, smart controls are revolutionizing how we think about lighting.

Smart Controls

Integrating LED lighting with smart control systems has been a game changer for warehouse operations. Using occupancy sensors and daylight sensors allows for automation based on real-time conditions; lights turn on when necessary and dim or shut off when workplaces are empty or fully illuminated by natural light. For example, a warehouse in New York reported a remarkable 20% boost in energy efficiency after implementing motion-sensor LED lights. This level of optimization cuts costs and fosters an adaptive environment that aligns with sustainability goals while enhancing operational productivity. As advancements in technology continue to shape our understanding, exploring the integral characteristics of LED systems further reveals their advantages in cold storage environments.

LED Technology for Cold Storage

One of the most crucial characteristics of LED lighting designed specifically for cold storage is its moisture and temperature resistance. Most commercial freezers and coolers do not have a moisture problem and if they do, something is seriously wrong, our High Bay LED Cold Storage fixtures are damp rated and do not require dust and water tight ratings. However, we do still offer IP65 rated products if those specific ratings are required. The LEDs typically carry an IP65 rating or higher, which means they are engineered to withstand dust and water spray—critical factors in a temperature-controlled environment where heavy condensation can often be a problem. By providing this essential protection, these lights promote safety by reducing electrical hazards and ensuring the longevity and efficiency of the lighting system itself.

In addition to moisture resistance, another significant aspect is the beam angle and lumen output. A beam angle around 120 degrees is ideal for delivering broad, uniform illumination throughout cold storage spaces. This wide spread ensures effective lighting in every corner without shadows that could obstruct visibility. However, narrower angles may be necessary when specific areas require focused lighting; for instance, a dedicated section for quality control might benefit from a more concentrated beam to highlight specific details that need attention.

Now let’s talk about lifespan because this feature greatly influences operational costs. One standout advantage of LED technology is its exceptionally long lifespan—rated at over 100,000 hours. This remarkable durability means you won’t need to replace fixtures as frequently as traditional options like fluorescent bulbs, saving both time and money on maintenance. Imagine reducing downtime in your operations simply by choosing a lighting solution that lasts longer and requires fewer replacements.

Finally, it’s essential to highlight the distinctive energy efficiency offered by LED lights. They consume significantly less power than traditional incandescent or even some fluorescent bulbs while providing superior brightness levels. This reduced energy usage translates to lower electricity bills and decreases the heat generated within cold storage areas—a vital factor in protecting perishable goods. As energy-efficient solutions become more essential in warehouse management, leveraging LED technology can lead to considerable long-term benefits. Make informed choices today to secure a brighter, more cost-effective future for your operations.

FAQ’s

How does the color temperature of LED lights affect visibility and safety in cold storage areas?

The color temperature of LED lights significantly impacts visibility and safety in cold storage areas by influencing how products and surfaces are perceived. Cooler color temperatures (5000K-6500K) enhance visibility, providing a daylight-like effect that improves contrast and reduces shadows, which is crucial for minimizing accidents in these environments. Studies suggest that proper lighting can reduce workplace accidents by up to 50%, highlighting the importance of choosing the right color temperature for optimal safety and efficiency in warehouse settings.

What factors should be considered when selecting LED fixtures for use in freezers or refrigerators?

When selecting LED fixtures for use in freezers or refrigerators, it’s crucial to consider factors such as temperature rating, lumen output, energy efficiency, and durability against moisture and temperature fluctuations. LEDs designed for extreme temperatures often maintain performance down to -30°C (-22°F) or lower. Additionally, a high Color Rendering Index (CRI) can enhance visibility of products while reducing energy costs by up to 75% compared to traditional lighting options. Proper selection not only ensures safety and efficiency but also extends the lifespan of the fixtures, making your cold storage operations more sustainable.

Are there specific LED products designed for extremely low-temperature environments?

Yes, there are specific LED products designed for extremely low-temperature environments, such as those used in cold storage warehouses and freezers. These specialized LEDs are built with materials that can withstand harsh conditions and maintain efficiency at temperatures as low as -40°F (-40°C). For example, LED fixtures with a high IP rating help resist moisture accumulation and ensure longevity. Moreover, energy efficiency is enhanced; studies show that using LED lighting in cold storage facilities can reduce energy consumption by up to 70% compared to traditional lighting options, leading to significant cost savings over time.

How does the energy efficiency of LED lights compare to traditional fluorescent lights in cold storage settings?

LED lights are significantly more energy-efficient than traditional fluorescent lights, particularly in cold storage settings where temperatures can affect performance. LEDs consume about 75% less energy than fluorescent bulbs and last up to 25 times longer. Additionally, they produce less heat, which is crucial for maintaining low temperatures in storage facilities. For instance, switching from fluorescent to LED lighting can reduce energy costs by up to 50%, making them a smart choice for warehouses aiming to cut expenses while enhancing illumination quality.

What installation best practices should be followed to optimize the performance of LED cold storage lighting?

To optimize the performance of LED cold storage lighting, it’s essential to ensure proper placement and spacing of fixtures to achieve uniform illumination while minimizing shadows and dark spots. Additionally, utilizing reflective surfaces can enhance light distribution and efficiency. According to studies, well-designed LED lighting systems can reduce energy consumption by up to 75% compared to traditional lighting options, which is crucial in low-temperature environments where energy efficiency directly impacts operational costs. Moreover, implementing smart control systems allows for adaptive lighting based on inventory movement, further improving energy savings and performance.